ELECTROLIFE project

About ELECTROLIFE

The ELECTROLIFE project aims to be a booster to enable the use of green hydrogen technologies to support decarbonization of European global industry. Currently, electrolysis technologies suffer from limitations in terms of cost, efficiency, stability, scalability, and recyclability. This is mainly due to the lack of understanding and identification of electrolyzer degradation mechanisms and improvement of current cell performance. In the next 5 years, ELECTROLIFE aims to increase the efficiency performance of electrolyzers by reducing the use of critical materials and extending the useful life of these systems. These goals will be achieved through test campaigns to identify multiple degradation mechanisms on multiple scales, multiphysics simulations with superimposed degradation mechanisms, prototyping of cells and stack components, and construction of dedicated test benches.

Objectives

The main objective of ELECTROLIFE is to understand the basic and cause-effect chains of aging mechanisms, to overcome the limited know-how on degradation phenomena, in order to model and design stacks and indicate day- by-day operation strategies to increase the lifetime of electrolysers, achieving the targets set by SRIA for 2030. the main objectives of ELECTROLIFE is divided into 11 sub- objectives (SO).

SO1: Data collection about degradation mechanism

SO2: Identification of degradation mechanisms and effects of their superposition by modelling and simulation activities validated by relevant experimental methods

SO3: Evaluate the impact of RES electrical profile on electrolysers durability in terms of the dynamic operating conditions

SO4: Modelling of degradation resulting from different degradation phenomena and operating conditions, including RES operation; models should be validated by experimental data

SO5: With the support of dynamic modelling, simulation of the transient electrical and thermal behavior in view of the impacts on degradation effects

SO6: Development of lifetime prediction models based on the degradation modelling; proposals may include verification testing for such models for selected technologies; defining predictive modelling of state-of-health / state-of-life for given operation, and on establishing operation solutions diminishing degradation

SO7: Development of operation solutions diminishing the degradation in stationary or transient operations

SO8: Adaptation or improvement of advanced characterization methods for deeper understanding by in- situ, ex-situ or in-operando analyses

SO9: Validation of novel solutions in short stack level (minimum 5 repeating units)

SO10: Development of uniform data formats that can potentially be used for machine learning and big data processing to identify and correlate cause and effect of degradation phenomena

SO11: Assessment of the improved durability on the lifecycle impact of the selected technologies

Concept

The ELECTROLIFE concept and architecture is unique because focus its research activities on all the 5 today classified electrolysis technologies, in order to approach with the same structured methodology all the paths to understanding and modeling the degradation mechanisms of different electrochemical systems, to develop and assess improved electrochemical cells and stacks (especially under dynamic use and operational stress) and to validate technologies and diagnostic tools (SoH). The ELECTROLIFE concept consist of 8 keystones (KS):

- KS1: Identification and comprehension of degradation phenomena that affect the 5 technologies involved

- KS2: Development of degradation and lifetime prediction models

- KS3: Development of testing procedures for degradation assessment

- KS4: Development of ad-hoc testing and diagnostic tools

- KS5: Technologies development and optimization

- KS6: Execution of test campaigns on the 5 electrolysis technologies

- KS7: Validation of the degradation models and diagnostic tools

- KS8: Guidelines for next generation robust stacks, diagnostic tools and optimized strategies of operation, for electrolysers lifetime extension

Approach

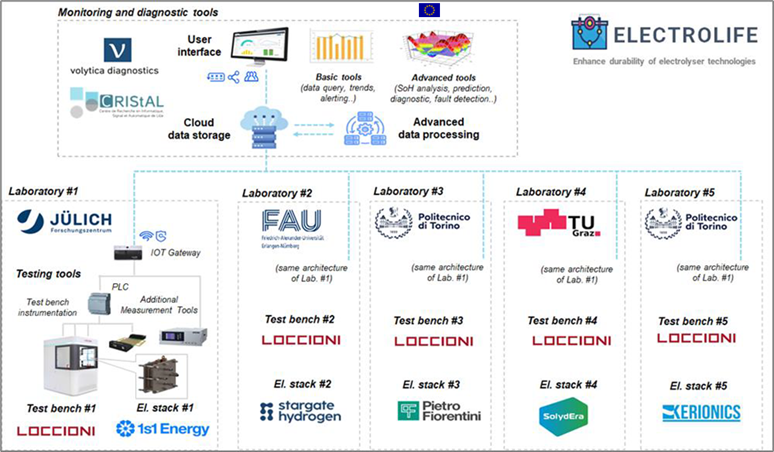

The combination of significant and diverse expertise in the Consortium, including the utilization of their infrastructures made available for the project, and methods adopted from different disciplines will be brought together and integrated to underpin all keystones of the concept, giving rise to a strong combined multidisciplinary approach for pursuing the ELECTROLIFE objectives. The results will flow into the project and to external scientific and industrial manufacturers communities, supported by coherent innovation and data management approach. The figure beside reproduces a schematic overview of the ELECTROLIFE methodological approach.

Structure

The ELECTROLIFE workplan is divided into:

- 6 research-related work packages;

- 1 dissemination work package;

- 1 management related work package.

Results

- Successful lab-scale demonstrators (TRL5) with long lasting performances, using relevant experimental methods: degradation rate (avg.): -25% for (AEL, PEMEL) and -50% for (AEMEL, SOEL); current density (avg.): + 50% for (AEL, PEMEL) and +100% for (AEMEL, SOEL).

- Validation of multiphysics models that include multi-mechanisms degradation;

- Development of SoH tool and advance prognostic/diagnostic tools for life extension;

- Produce high performance techs with lower content of CRM allowing scalability and recyclability;

- CAPEX and OPEX reduction (avg.) of about 40% for (AEL, PEMEL) and more than 70% for (AEMEL, SOEL);

- +25 Publications on scientific papers;

- At least 7 postdoctoral researchers/PhD students trained.

Facts and figures

Acronym: ELECTROLIFE

Duration: 60 months

Start date: 01 January 2024

End date: 31 December 2028

Total budget: €9.995.705,00

Publications

ELECTROLIFE will disseminate scientific results to peers in the field by means of scientific publications. All relevant publications will be posted on this website.