Our partners TUG and SE have recently published a new ELECTROLIFE article titled “Dual pathways for refinery off-gas processing: Comparative analysis of steam reforming and co-electrolysis” in Energy Conversion and Management.

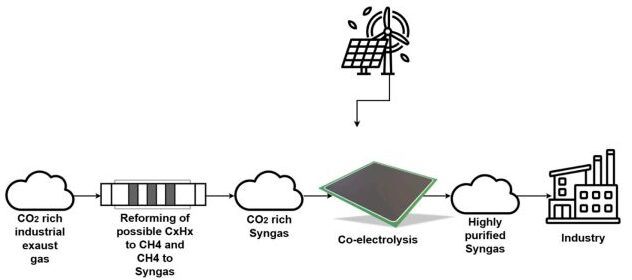

The study provides a systematic comparison of steam methane reforming and co-electrolysis, as well as their potential integration for sustainable syngas and hydrogen production. Both processes were investigated under realistic industrial conditions, enabling the identification of key parameters governing performance and stability. Pt-based catalysts demonstrated excellent thermal stability, strong resistance to deactivation, and near-equilibrium methane conversion, confirming their suitability for large-scale reforming applications.

Co-electrolysis was assessed in solid oxide electrolysis cells (SOECs) over a wide range of gas compositions, including pure CO₂ electrolysis as a strategy for pre-electrolysis hydrogen removal. Electrochemical performance was analysed using impedance spectroscopy, distribution of relaxation times (DRT), and current–voltage characterisation. The results confirm the superior stability and performance of Pt-based catalysts under high-throughput conditions, while Ni-based systems showed greater sensitivity to operational fluctuations.

To enable optimal SOEC operation, the study proposes the addition of steam downstream of the reformer to fine-tune the reformate composition. Overall, the findings demonstrate that coordinated optimisation of reforming and electrolysis conditions offers a promising pathway for sustainable syngas production powered by renewable electricity and lays a strong foundation for the further development of integrated thermo-electrochemical systems tailored to industrial off-gas streams.

Congratulations to our partners on this outstanding achievement!