We are happy to share that Volytica Diagnostics hosted a workshop that brought together all ELECTROLIFE partners. The main focus of the gathering was to discuss and define the essential characteristics and boundary conditions of an advanced monitoring system for electrolysers used in green hydrogen production.

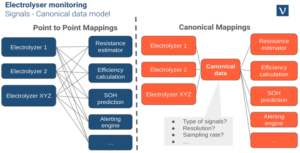

The discussions started with a deep dive into cloud-based monitoring, where the benefits of cloud-based monitoring of electrolysers were outlined and discussed. The consensus was that a single monitoring solution offers immense potential in terms of scalability and gains through comparison between similar systems, e.g. through data-based algorithms or AI/ML. A key takeaway from the workshop was the critical importance of monitoring industrial electrolysers. Experts agreed that without “digital electrolyser intelligence”, it would be impossible to achieve the levels of safety, performance optimisation, and lifespan extension necessary for large-scale industrial operations. The partners identified essential signals, sensors, and KPIs that should be monitored for safety and performance and for predicting the system’s lifespan, which could then be used to fine-tune usage profiles. The result of the discussion was used to derive a so-called Canonical Data Model (CDM). This model allows for a universal, adaptable monitoring solution that works across all types of electrolyser systems. By standardising communication and reducing setup efforts, the CDM simplifies the process of integrating cloud-based monitoring solutions, while also cutting down on computing power and costs. Finally, the workshop explored the extension of electrolyser lifetimes. The ELECTROLIFE consortium has models and simulation tools to predict the lifetime of materials, components and systems as a function of operating conditions, which is the basis for application-specific optimisation.

Volytica shared its innovative approach to lifetime prediction, which uses stress maps to assign ageing rates to different operating conditions. This allows operators to assess system stress in real time and adjust operations to ensure that ageing remains within acceptable limits.

The workshop marked a significant step forward in defining the future of electrolyser monitoring, bringing us closer to more efficient, safe, and optimised systems for green hydrogen production. We’re looking forward to continuing this journey toward a greener, more sustainable energy landscape!